Yam Drying Room

Energy-saving and Eco-friendly Design

Efficient and Sustainable Yam Drying

Precise Temperature Control

Good Drying Quality

Clean and Hygienic

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

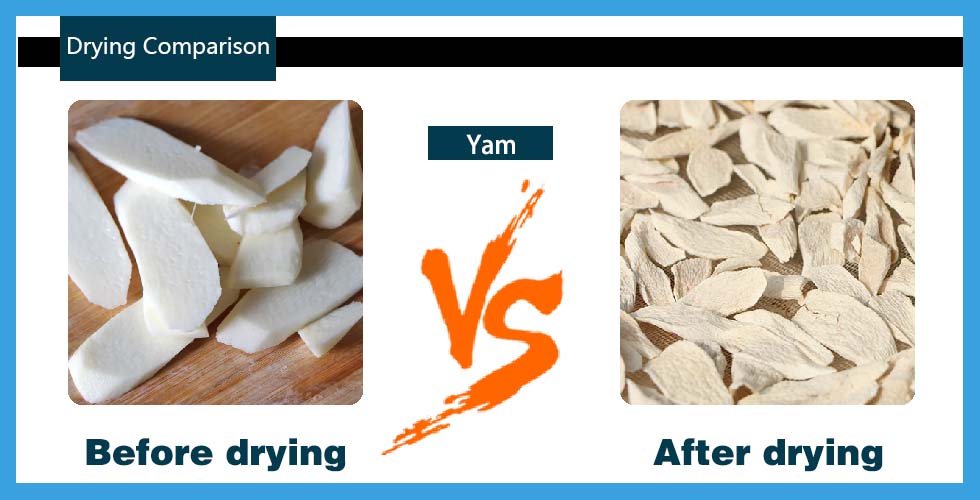

The yam dryer is a specialized machine designed to efficiently dry yam slices while preserving their nutritional value and quality. Huai yam, known for its high nutritional content, is carefully prepared before the drying process. To prepare Huai yam for drying, it is first peeled and sliced into uniform thickness and size. This ensures even drying and consistent results. The slices then undergo a water treatment process to remove excess moisture, preparing them for the drying stage.

Ⅰ.Construction Of The Yam Drying Room:

Drying machine is made of heating system (including but not limited to coal/firewood, wooden pellets, gas, biogas, steam, liquid fuel, electricity etc ),drying room, certain number movable carts inside to load drying materials.There are usually 2/4/6/8/10/12/18/24 movable carts inside based on different capacity.

Ⅱ.Air Source Heat Pump Drying Principle:

First, push carts with loaded fresh materials inside, then setting drying temperature, humidity and time. After hot air generated from heating system, anti-high temperature & humidity fans will circulate hot air across fresh materials laying on each tray of carts evenly inside drying room, humidity emitting fans start to work when the moisture reaches setting data. During drying process, when temperature reaches setting data, heat system will automatically shut down to achieve energy-saving effects. After well-drying, pull out carts containing dried materials. And prepare for next batch drying. Clients are suggested to have double quantity of carts to avoid energy waste during fresh materials loading time.

Ⅲ.Advantages of Yam Dryer:

- 01High Efficiency and Energy-saving: Precise temperature control, energy-saving and eco-friendly design and integration for efficient and sustainable yam drying.

- 02Good Drying Quality: Uniform shape, consistent color, and high-quality yam slices.

- 03Clean and Hygienic: Sealed dryer prevents outside pollutants, new air energy heat pump ensures green quality of dried yam chip.

Technical Parameters

| Model | Length*width*height(mm) | Heat pump power (P) (Copeland compressor) |

Number of small carts (vehicles) |

Number of pallets (pcs) |

Number of fans (units) |

Pallet size 10 layers(mm) |

Approximate drying yield/batch (kg) |

| 4-car side air supply | 4500*2300*2100 | 3 | 4 | 40 | 2 | 1400*900 | 1200 |

| 4 car rear air supply | 6000*1800*2500 | 7 | 4 | 40 | 4 | 1400*900 | 1200 |

| 6 car rear air supply | 6500*2300*2500 | 7 | 6 | 60 | 6 | 1400*900 | 1800 |

| 8 car rear air supply | 8000*2300*2500 | 7 | 8 | 80 | 6 | 1400*900 | 2400 |

| 10 car rear air supply | 7000*3300*2500 | 15 | 10 | 100 | 8 | 1400*900 | 3000 |

| 12 car rear air supply | 8000*3300*2500 | 15 | 12 | 120 | 8 | 1400*900 | 3600 |

| 18 car rear air supply | 8000*4800*2600 | 2*15 | 18 | 180 | 10 | 1400*900 | 5400 |

| 24 car rear air supply | 8000*6200*2600 | 2*15 | 24 | 240 | 12 | 1400*900 | 7200 |

| The above parameters are for reference only and capacity is specific to the yam to be dried. | |||||||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.