-scaled.jpg)

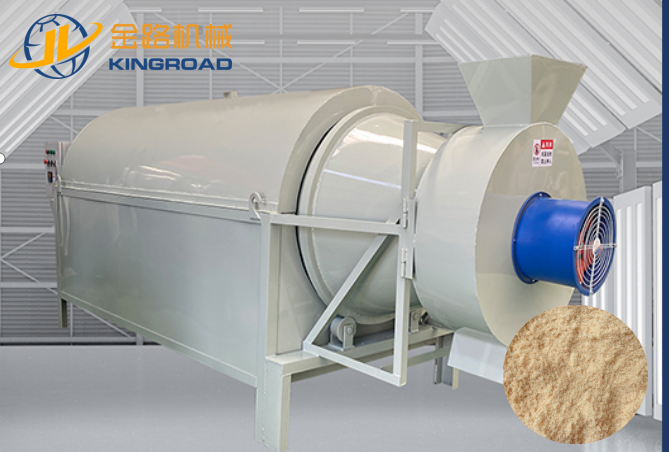

Sawdust Rotary Dryer

Low Price

High Production Capacity

Energy Efficient

User-Friendly

High Efficiency

Environmentally Friendly

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Introduction to the Drum Dryer

The drum dryer is a new type of high-efficiency and energy-saving electric heating drying machine. It adopts a drum-shaped structure and features uniform heating, automatic rotation, automatic mixing, and automatic discharging. The drum continuously rotates during operation to achieve the purpose of drying. It is easy to operate and saves time, labor, and effort. The dryer maintains cleanliness and hygiene, and offers many advantages, including energy efficiency, rapid temperature rise, uniform heating, and temperature control. It is suitable for drying various materials.

Advantages of the Drum Dryer

Low cost and high production capacity: The drum dryer has a large processing capacity and consumes less fuel, resulting in low drying costs.

High temperature resistance: The dryer can withstand high temperatures and utilize high-temperature hot air for fast drying of materials.

Strong scalability: The design of the dryer takes into account production surplus, so even with a slight increase in production volume, there is no need to replace the equipment.

Efficient drying: The drum dryer ensures efficient and uniform drying of materials, resulting in high-quality dried products.

Versatility: The drum dryer is suitable for drying a wide range of materials, including agricultural products, chemicals, minerals, and more.

Easy maintenance: The drum dryer is designed for easy operation and maintenance, minimizing downtime and maximizing productivity.

Applications of Drum Dryers:

- Chemical, mining, and metallurgical industries: Drum dryers are used for drying materials such as ores, slag, coal, metal powders, clay, diatomaceous earth, kaolin, and bauxite.

- Agriculture, feed, and fertilizer industries: Drum dryers are suitable for drying materials like straw, grass, leaves, fish meal, corn sauce, starch residue, distiller's grains, pharmaceutical residues, fruit residues, soy sauce residues, bagasse, grass charcoal, organic compound fertilizers, sludge, waste from aquatic products, waste from food factories, waste from slaughterhouses, organic fertilizers, inorganic fertilizers, and ammonium phosphate fertilizers.

|

Rotary Tube Drying Machine |

||||||

|

Dimension |

Capacity(KG) |

Roller size |

Dynamics(KW) |

Heating power(KW) |

Dehumidifier fan(W) |

Speed Reducer Model |

|

3000*1100*1450mm |

200 |

800*1800*3mm |

1.5 |

30 |

150 |

ZQ200 |

|

3800*1100*1450mm |

300 |

800*2600*3mm |

2.2 |

30-40 |

150 |

ZQ200 |

|

3100*1300*1500mm |

300 |

1000*2000*3mm |

2.2 |

30-40 |

150 |

ZQ200 |

|

4000*1250*1650mm |

500 |

1000*2800*3mm |

3.0 |

40-50 |

170 |

ZQ200 |

|

4800*1500*1700mm |

1000 |

1200*3400*4mm |

4.0 |

60-80 |

370 |

ZQ250 |

|

6000*1800*2100mm |

2000 |

1500*4400*5mm |

7.5 |

80-100 |

370 |

ZQ350 |

|

7800*1800*2100mm |

3000 |

1500*6000*5mm |

11.0 |

120-150 |

370 |

ZQ350 |

|

9000*2300*2500mm |

5000 |

1800*6600*8mm |

15.0 |

180-200 |

550 |

ZQ500 |

|

Remark: heating source can be electricity, coal, wooden pellets etc. |

||||||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.