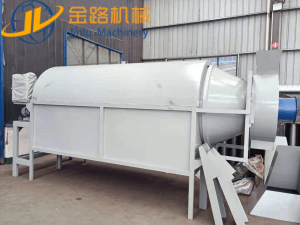

Cat Litter Drying Machine

Environmentally Friendly

Energy-saving

Simple Operation

High Productivity and Efficiency

Versatile

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

Principle of the Cat Litter Drying Machine

The drying heat sources for a tumble dryer include electric heating, coal and wood heating, gas heating, and biomass pellet combustion. Therefore, the material that needs to be dried enters the drum through the feeding port and is lifted upwards by the lifting plates. Under the force of gravity and the rotation of the drum, the material is continuously scattered and falls down at the upper end, forming a uniform curtain inside the drum. It fully exchanges heat with the hot airflow inside the drum. As the material is repeatedly scattered, the moisture it contains gradually dries out, achieving the purpose of drying.

Brief Introduction of the Cat Litter Drying Machine

New Energy-Efficient Electric Heating Dryer adopts a drum-type structure, featuring uniform heating, automatic rotation, automatic stirring, and automatic discharging. The drum continuously rotates during operation for drying purposes. It is easy to operate, saving time, labor, and manual effort. The dryer maintains cleanliness and hygiene and offers numerous advantages, including energy-saving, quick temperature rise, uniform heating, and temperature control. It is suitable for roasting and drying a variety of materials.

Characteristics of the Cat Litter Drying Machine

- 01Versatile: Suitable for roasting and drying a variety of materials.

- 02High productivity and efficiency: Provides rapid heating, energy efficiency, and reduces reliance on manual labor compared to traditional dryers.

- 03Energy-saving: Utilizes a low-power motor drive and optimized gear system.

- 04Simple operation: Features automatic temperature control for uniform drying and can be operated by a single person.

- 05Environmentally friendly: Uses electric heating to eliminate open flames, reduce smoke, and dust.

Technical Parameters

|

Rotary Tube Drying Machine |

||||||

|

Dimension(mm) |

Capacity(KG) |

Roller size(mm) |

Power(KW) |

Heating power(KW) |

Dehumidifier fan(W) |

Speed Reducer Model |

|

3000*1100*1450 |

200 |

800*1800*3 |

1.5 |

30 |

150 |

ZQ200 |

|

3800*1100*1450 |

300 |

800*2600*3 |

2.2 |

30-40 |

150 |

ZQ200 |

|

3100*1300*1500 |

300 |

1000*2000*3 |

2.2 |

30-40 |

150 |

ZQ200 |

|

4000*1250*1650 |

500 |

1000*2800*3 |

3.0 |

40-50 |

170 |

ZQ200 |

|

4800*1500*1700 |

1000 |

1200*3400*4 |

4.0 |

60-80 |

370 |

ZQ250 |

|

6000*1800*2100 |

2000 |

1500*4400*5 |

7.5 |

80-100 |

370 |

ZQ350 |

|

7800*1800*2100 |

3000 |

1500*6000*5 |

11.0 |

120-150 |

370 |

ZQ350 |

|

9000*2300*2500 |

5000 |

1800*6600*8 |

15.0 |

180-200 |

550 |

ZQ500 |

|

Remark: Heat source can be electricity, coal, wooden pellets etc. |

||||||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.