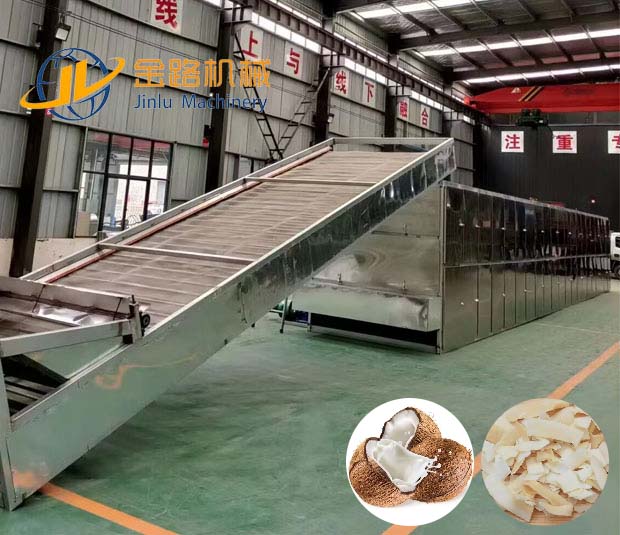

Coconut Dryer

Versatile and widely used for drying grain materials,fruit,herb, vegetables etc.

24-hour continuous working avoiding heat waste.

Fully auto and labor saving, 1-2 workers can operate.

Large capacity.

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

Coconut jerky is a food made from dried coconut meat, which is rich in calories, fat, and fiber. The dried coconut is rich in Coconut oil, and its main component is medium chain fatty acids. These fatty acids can be directly used by the body, helping to promote metabolism and reduce fat. In addition, dried coconut also contains various nutrients, such as minerals manganese, potassium, magnesium, as well as vitamins B1 and B2.

Ⅰ.Construction Of Coconut Dryer:

The mesh belt dryer consists of a feeder conveyor, an equally distributed bar for material distribution, a main drying body with 5-7 layers of stainless steel mesh belts, optional heat source, a centrifugal fan for hot air circulation, humidity exhaust fans, an output conveyor belt, gear-drive equipment, and panel control. The width of the mesh belt dryer is 2-3 meters, while the length and number of layers can be customized according to the client's capacity. Usually, it is recommended to have a length of at least 7 meters for cost-effectiveness.

Ⅱ.Working Principle Of Coconut Dryer:

The coconut is transported to the top layer of the drying body through a belt conveyor and then falls onto the mesh belt. With the continuous movement of the mesh belt,the coconut undergoes dynamic drying as it moves from the top layer to the bottom without any interruptions.During this process, the coconut is automatically reversed each time it falls onto the lower layer, which accelerates the drying process. Compared to other drying machines, the mesh belt dryer requires less time to dry the same materials.Following heat source is optional according to your local fuel.

The mesh belt dryer is a highly advanced drying machine that utilizes continuous hot air circulation for efficient drying. It ensures minimal heat waste and is widely employed in the drying of large quantities of materials.

Ⅲ.Coconut Dryer Machine Applications:

The coconut dryer is a versatile drying equipment that incorporates the experience gained from thousands of drying cases, resulting in optimized drying processes for various materials. It is capable of drying a wide range of items, such as sweet potatoes, cassava, peppers, onions, ginger, garlic, potato chips, moringa leaves, wood, and more. Its versatility makes it suitable for diverse applications.

Ⅳ.Advantages Of Chilli Dryer Machine:

- 01High drying efficiency:The drying machine not only relies on heat to dry , but also through the strong air, improve the drying efficiency and reduce the drying time.

- 02Large capacity: Continuous feeding and discharging material.

- 03 Save cost, easy to operate,1-2 workers are enough.

Technical Parameters

| Model | JL-1*10m | JL-1*12m | JL-1*17m |

| Layer | 3layers,4 layers,5 layers,6 layers,7 layers | ||

| Material thickness | 50-200mm | ||

| Drying temperature | 40-120℃ | ||

| Drying time | 0.5-5hours | ||

| Moisture reduce | 75%-80%(customized) | ||

| Main equipment motor | 2.2kw | 2.2kw | 2.2kw |

| Hot air draft fan | 10C-15.5KW | 10C-18.5KW | 12C-30KW |

| Materials discharge conveyor | 0.12KW(Gear speed regulating motor) | ||

| The above parameters are for reference,we can provide suitable solution according to customer's requirements. | |||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.