Chrysanthemum Dryer

Versatile and widely used for drying grain materials,fruit,herb, vegetables etc.

24-hour continuous working avoiding heat waste.

Fully auto and labor saving, 1-2 workers can operate.

Large capacity.

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

Dried chrysanthemums are rich in volatile oil, inulin, amino acids, vitamins, and other ingredients. Drinking dried chrysanthemums in water has the effects of clearing the eyes and fatigue, calming the mind and refreshing the mind, degrading fire energy, and replenishing water. It can alleviate visual fatigue, supplement the body's necessary nutrients, and have the effects of antioxidation, protecting the oral cavity, refreshing the breath, and regulating the complexion.

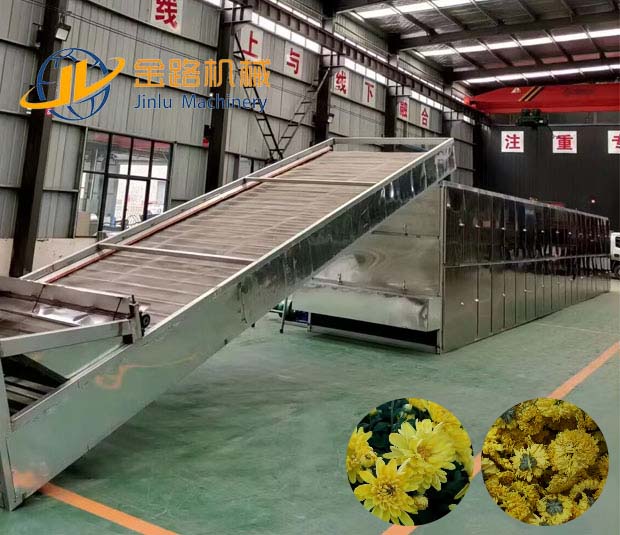

Ⅰ.Construction Of Chrysanthemum Dryer:

The mesh belt dryer consists of a feeder conveyor, an equally distributed bar for material distribution, a main drying body with 5-7 layers of stainless steel mesh belts, optional heat source, a centrifugal fan for hot air circulation, humidity exhaust fans, an output conveyor belt, gear-drive equipment, and panel control. The width of the mesh belt dryer is 2-3 meters,while the length and number of layers can be customized according to the client's capacity. Usually, it is recommended to have a length of at least 7 meters for cost-effectiveness.

Ⅱ.Working Principle Of Chrysanthemum Dryer:

The chrysanthemum is transported to the top layer of the drying body through a belt conveyor and then falls onto the mesh belt. With the continuous movement of the mesh belt,the chrysanthemum undergoes dynamic drying as it moves from the top layer to the bottom without any interruptions.During this process, the chrysanthemum is automatically reversed each time it falls onto the lower layer, which accelerates the drying process. Compared to other drying machines, the mesh belt dryer requires less time to dry the same materials.Following heat source is optional according to your local fuel.

The mesh belt dryer is a highly advanced drying machine that utilizes continuous hot air circulation for efficient drying. It ensures minimal heat waste and is widely employed in the drying of large quantities of materials.

Ⅲ.Advantages Of Chilli Dryer Machine:

- 01 Uniform drying effect: The Chrysanthemum keep moving on the belt, during this process, both side of the material can fully contact the hot air, so that the drying effect can be uniform.

- 02Adjustable speed: Drying temperature,moisture can be ajusted by the control panel by adjust the mesh belt running speed and air rate.

- 03 Optional Heat Source: Electricity, coal,firewood, wooden pellets, gas,etc optional heating source.

Technical Parameters

| Model | JL-1*10m | JL-1*12m | JL-1*17m |

| Layer | 3layers,4 layers,5 layers,6 layers,7 layers | ||

| Material thickness | 50-200mm | ||

| Drying temperature | 40-120℃ | ||

| Drying time | 0.5-5hours | ||

| Moisture reduce | 75%-80%(customized) | ||

| Main equipment motor | 2.2kw | 2.2kw | 2.2kw |

| Hot air draft fan | 10C-15.5KW | 10C-18.5KW | 12C-30KW |

| Materials discharge conveyor | 0.12KW(Gear speed regulating motor) | ||

| The above parameters are for reference,we can provide suitable solution according to customer's requirements. | |||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.