Apple Drying Room

Convenient and User-friendly

Versatile Application

Customizable Trays

Durable and Hygienic Construction

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

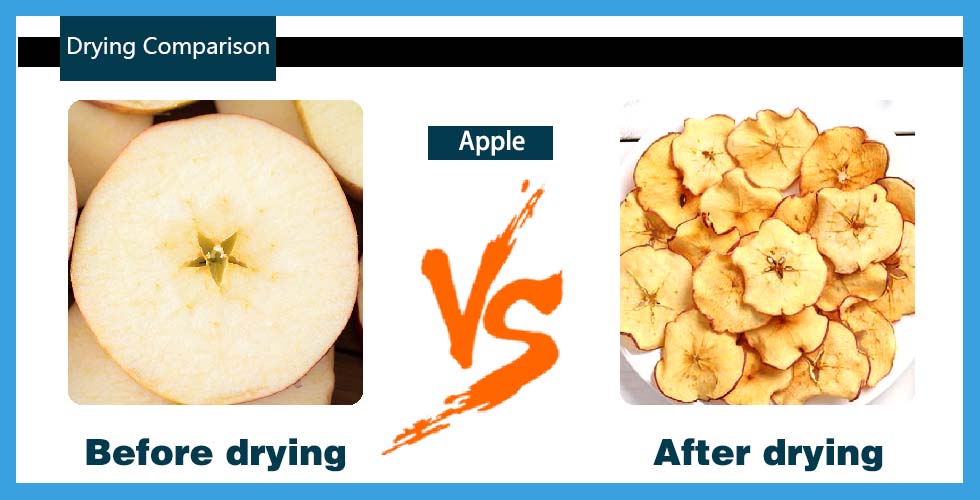

The apple dryer is a specialized machine designed to efficiently dry apples and preserve their quality. Using advanced drying technology, it effectively removes moisture from the apples while maintaining their natural flavor, aroma, and nutritional content.The dryer operates by utilizing a combination of heat and airflow. The heat is generated by an energy-efficient system that absorbs heat from the external environment. This heat is then transferred to the drying chamber where the apples are placed. The controlled airflow circulates around the apples, ensuring even drying and preventing material sticking.

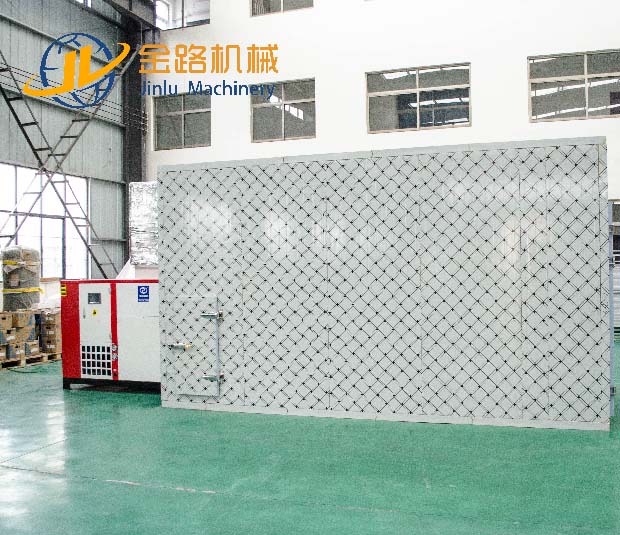

Ⅰ.Construction Of The Apple Drying Room:

Drying machine is made of heating system (including but not limited to coal/firewood, wooden pellets, gas, biogas, steam, liquid fuel, electricity etc ),drying room, certain number movable carts inside to load drying materials.There are usually 2/4/6/8/10/12/18/24 movable carts inside based on different capacity.

Ⅱ.Air Source Heat Pump Drying Principle:

First, push carts with loaded fresh materials inside, then setting drying temperature, humidity and time. After hot air generated from heating system, anti-high temperature & humidity fans will circulate hot air across fresh materials laying on each tray of carts evenly inside drying room, humidity emitting fans start to work when the moisture reaches setting data. During drying process, when temperature reaches setting data, heat system will automatically shut down to achieve energy-saving effects. After well-drying, pull out carts containing dried materials. And prepare for next batch drying. Clients are suggested to have double quantity of carts to avoid energy waste during fresh materials loading time.

Ⅲ.Advantages Of The Dryer Compared To Traditional Heat Pump Dryer:

- 01 Energy-saving: Efficient use of input electricity and absorption of free heat from the air.

- 02 All-in-one Design: No installation required, simply connect to power supply for operation.

- 03 Easy Opening: High-grade fingerless stainless steel magnetic door.

- 04 Effective Drying: Parallel penetration of strong wind for even and thorough drying.

- 05 Intelligent Operation: Touch screen interface for convenient and automated drying.

- 06 Portable and Versatile: No external parts, can be easily moved and used anywhere.

Technical Parameters

| Model | Length*width*height(mm) | Heat pump power (P) (Copeland compressor) |

Number of small carts (vehicles) |

Number of pallets (pcs) |

Number of fans (units) |

Pallet size 10 layers(mm) |

Approximate drying yield/batch (kg) |

| 4-car side air supply | 4500*2300*2100 | 3 | 4 | 40 | 2 | 1400*900 | 1200 |

| 4 car rear air supply |

6000*1800*2500 |

7 | 4 | 40 | 4 | 1400*900 | 1200 |

| 6 car rear air supply | 6500*2300*2500 | 7 | 6 | 60 | 6 | 1400*900 | 1800 |

| 8 car rear air supply | 8000*2300*2500 | 7 | 8 | 80 | 6 | 1400*900 | 2400 |

| 10 car rear air supply | 7000*3300*2500 | 15 | 10 | 100 | 8 | 1400*900 | 3000 |

| 12 car rear air supply | 8000*3300*2500 | 15 | 12 | 120 | 8 | 1400*900 | 3600 |

| 18 car rear air supply | 8000*4800*2600 | 2*15 | 18 | 180 | 10 | 1400*900 | 5400 |

| 24 car rear air supply | 8000*6200*2600 | 2*15 | 24 | 240 | 12 | 1400*900 | 7200 |

| The above parameters are for reference only and capacity is specific to the apple to be dried. | |||||||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.